3D Printed Angular contact ball bearing with 8mm BB bullet

2020/06/12 categories:3D Printer| tags:3D Printer|Bearing|angular bearing|

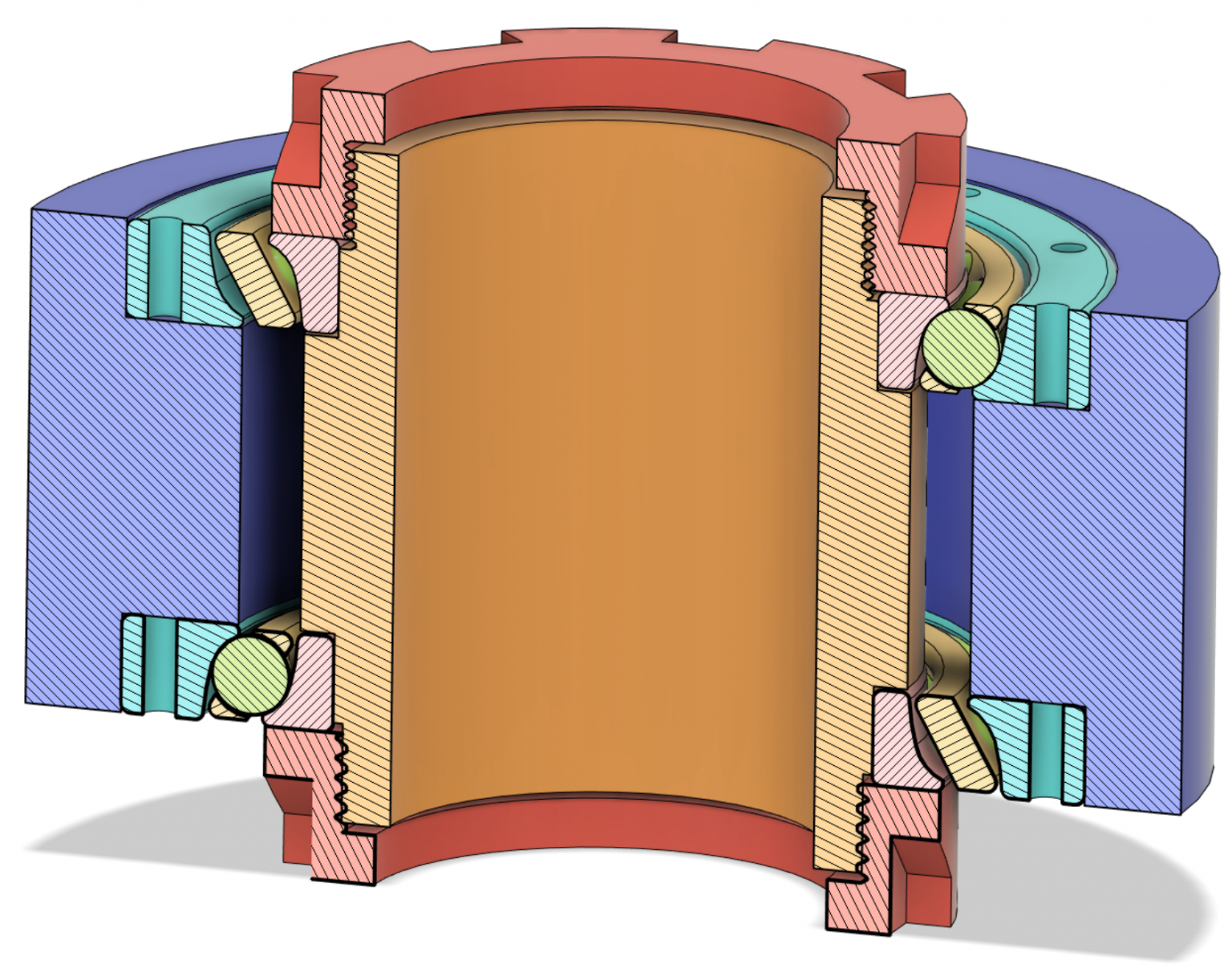

Continuing from the previously created [4 point contact ball bearing made with 3D printer and 8mm BB bullet] (https://ymt-lab.com/3dprinted-ball-bullet-bearing/), I tried to make another BB bullet bearing. .. The bearing to be made this time is an angular contact ball bearing.

Specification

- Outer diameter Φ100、Inner diameter Φ50、Thickness12

- 8mm BB bullet

- 21 balls

- Contact angle 45°

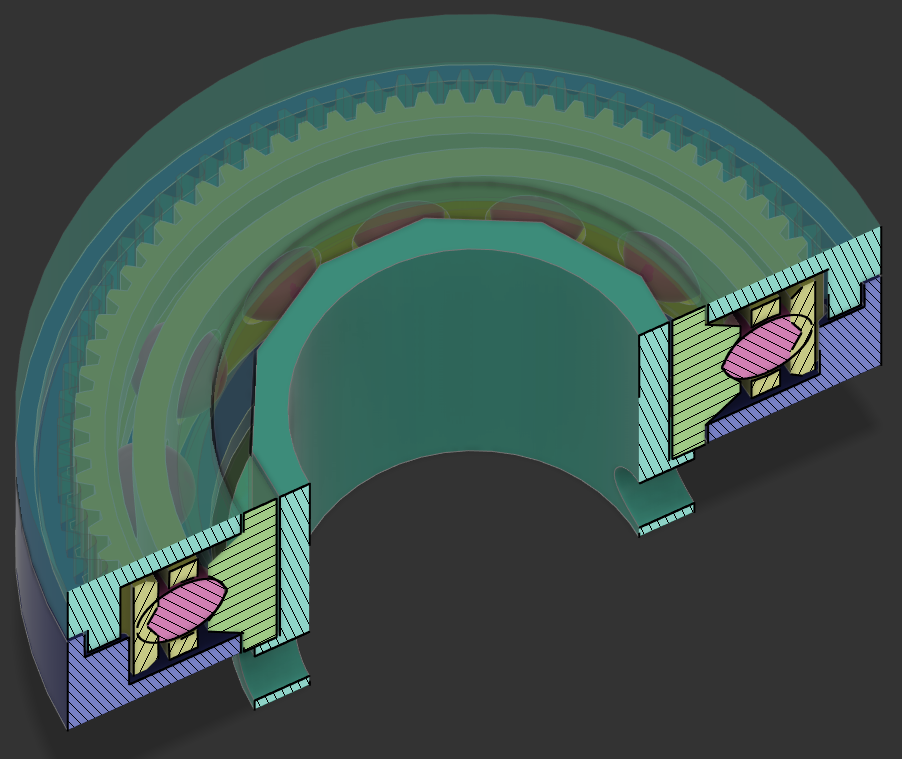

The cross section is an example of back-to-back alignment. The reason why there are more screw holes on the outer ring is that when I read the manufacturer’s catalog of the cross roller ring, it was stated that the more bolts there are, the more stable it is.

30 ° seems to be a general contact angle, but this time I set it to 45 ° for the time being. Looking at the bearing manufacturer’s catalog, there are about 15 to 60 °, and as the contact angle increases, it becomes stronger against axial load and weaker against radial load, and it seems to be used for low rotation. If it is for a ball screw support, it will receive a considerable axial load depending on the application, so it seems to use one with a contact angle of 55 ° or 60 °. On the contrary, in the case of a high-speed spindle, it seems that a shallow one such as 15 ° or 20 ° is used.

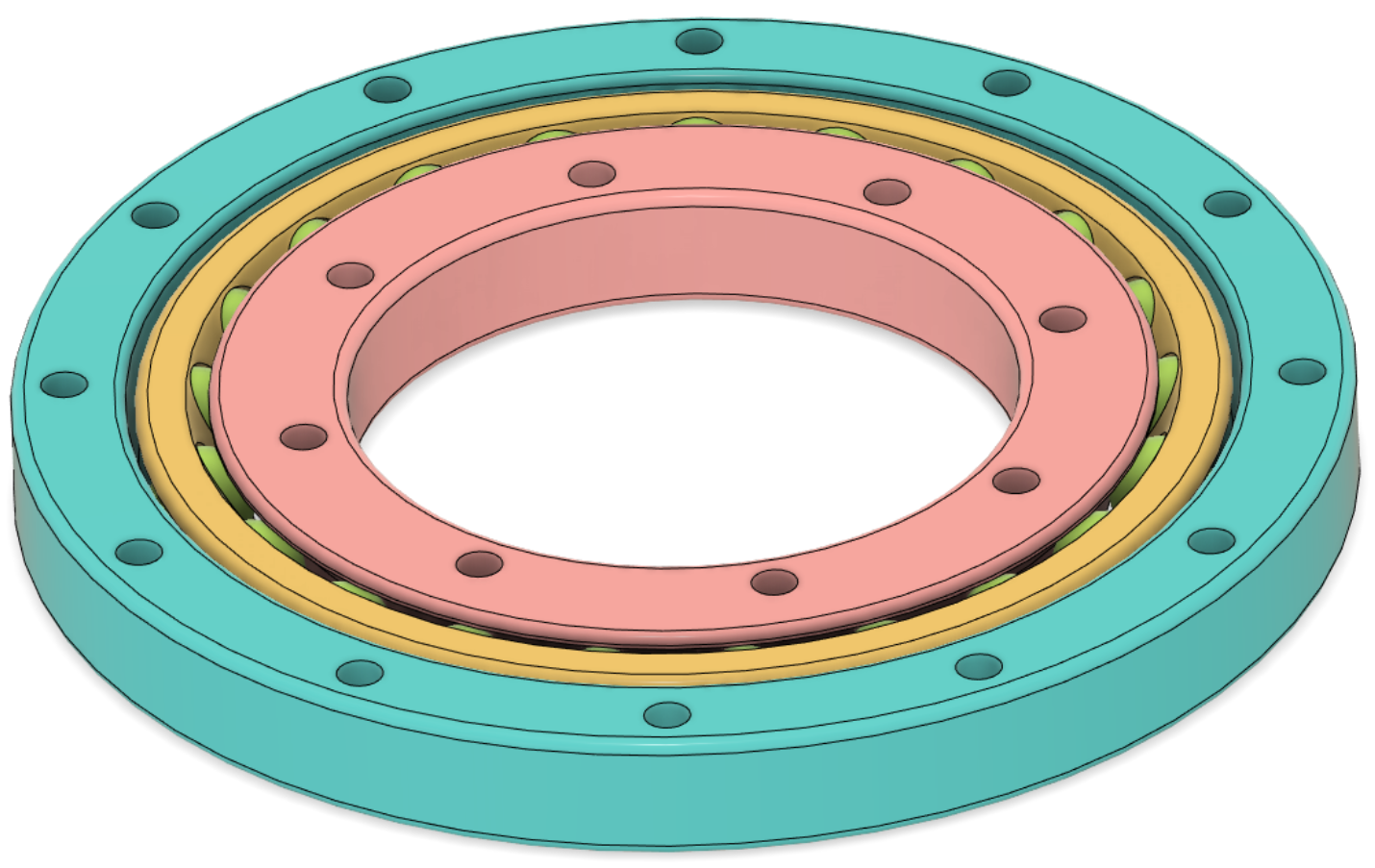

Sketch

The sketch looks like this. The contact angle was 45 °, the outer diameter was 100 mm, and the hollow diameter was 50 mm. The inner and outer rings have holes for mounting M3 truss screws. The shape of the orbital surface is R5, which is slightly larger than the diameter of the 8mm BB bullet.

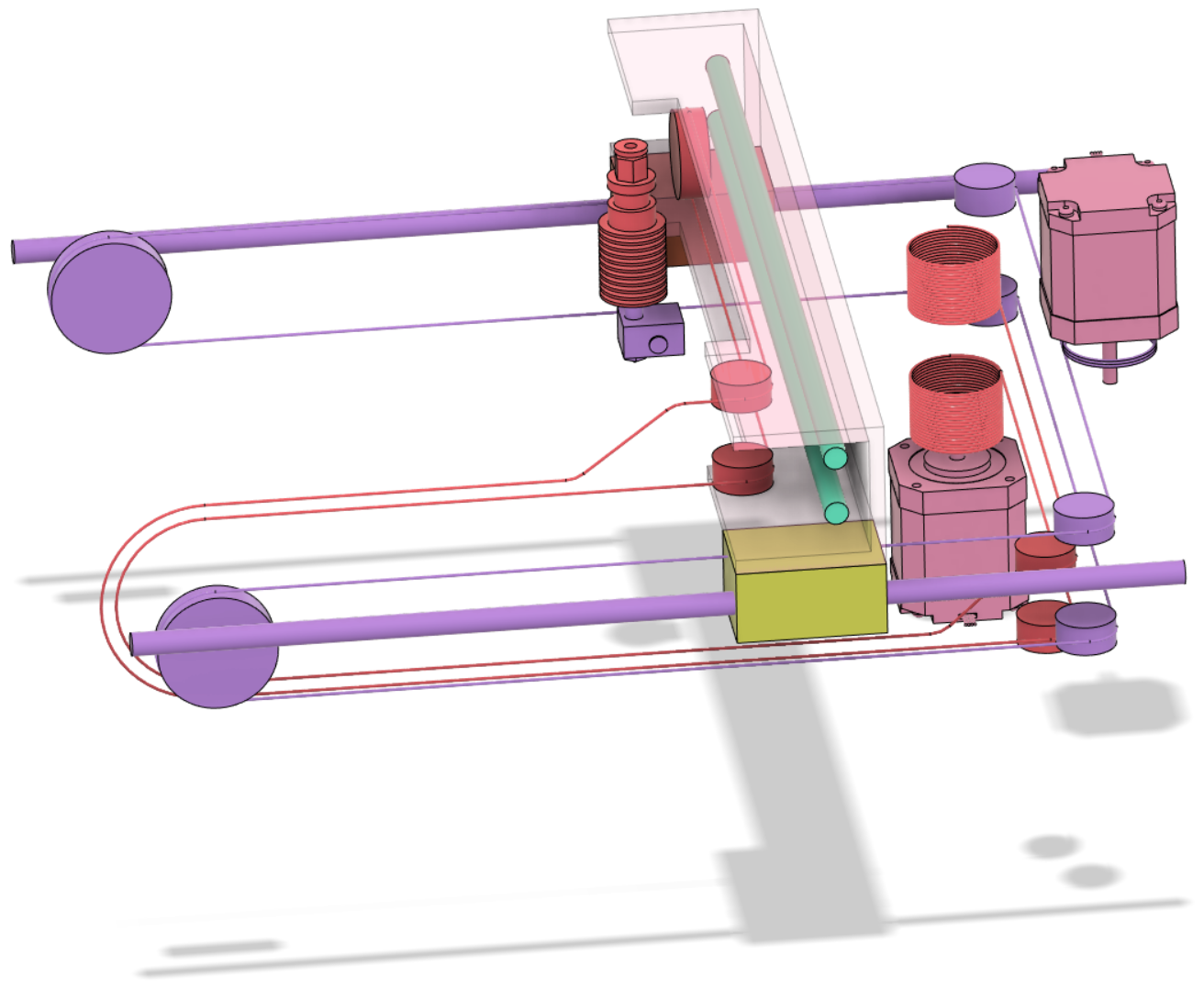

Example of use

This is an example of fixing with a locknut without the fixing hole of the inner ring.

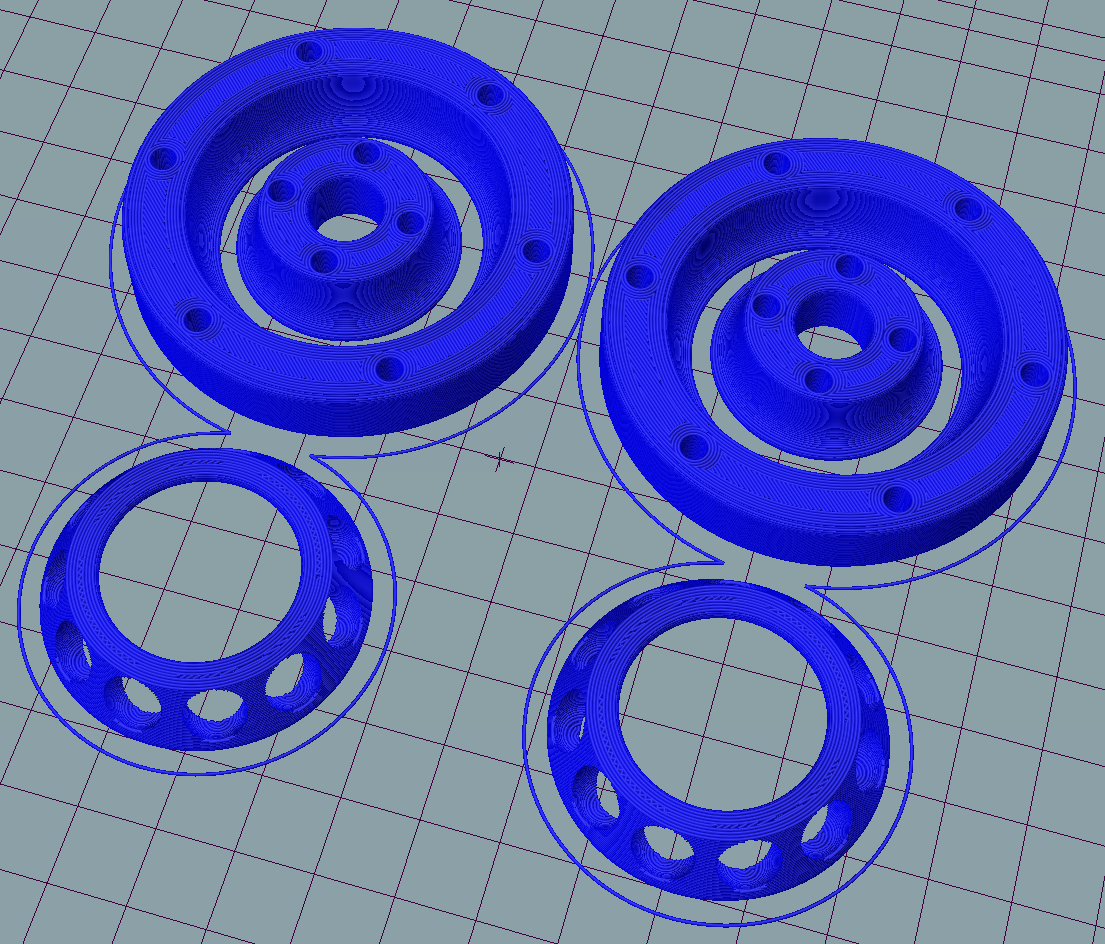

3D printing

As usual, it has a lot of resistance, so it is not suitable for high rotation, but thanks to the pressurization, there is no play and the rigidity is high.