Consider wire driving of a 3D printer

2020/05/13 categories:3D Printer| tags:3D Printer|Wire driven|

I thought it was amazing to see a wire-driven robot on Youtube, so I quickly modeled the wire-driven 3D printer and thought about what it would look like.

Wire drive features

Can you think of the following characteristics of wire drive?

- Wire elongation is low (nearly zero?)

- Wires are lighter than belts and ball screws, so inertia is reduced.

- Force can be amplified using the pulley principle

- Smaller than belts and ball screws

- Separate the drive source

Is a bicycle wire a common use case? It seems that there is a mechanism that uses wires for various things unexpectedly, such as being included in old film single-lens reflex cameras.

Find out the minimum bend radius of the wire

Since this is my first time designing with wires, I investigated the minimum bending radius.

First of all, when I searched for wire with monotaro, a product called wire rope stainless steel was hit and the diameter was 1, 1.5, 2, 3, 4, 6 mm, so I tentatively selected Φ1 mm x 5 m for the time being. It seems that the composition of the wire is related to the minimum bending radius when various googles are made. When I checked the composition of Monotaro’s Φ1mm wire, it said 7x7, so when I looked up the Φ1mm 7x7, it said as follows.

The diameter of the pulley of the 7x7 structure rope is 40 times or more the diameter of the rope used.

When D ≤ 8 2D

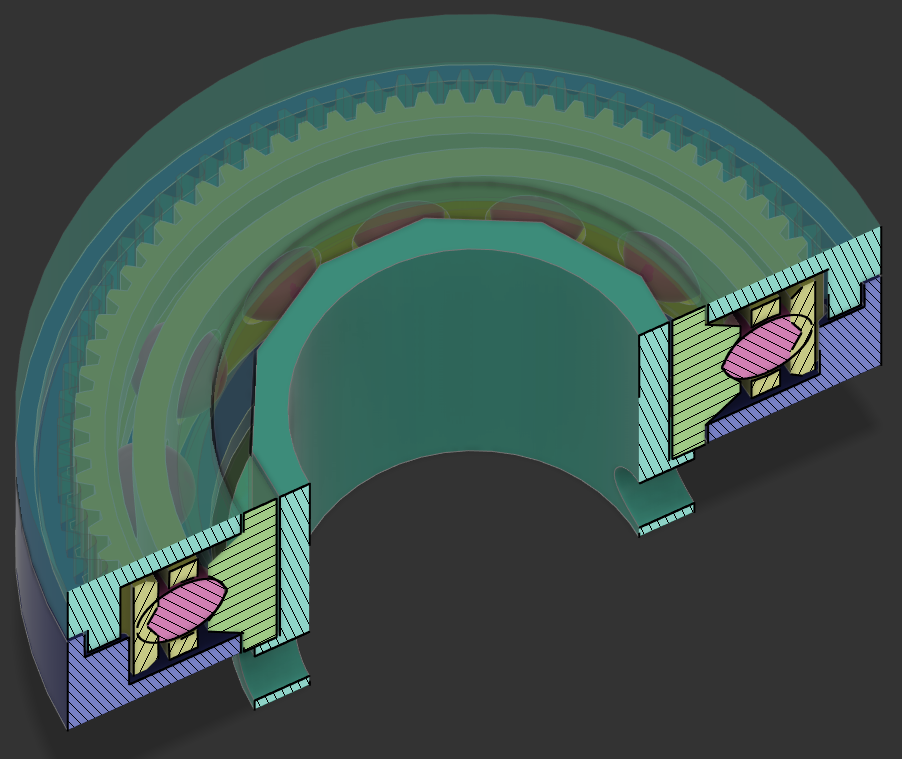

In the case of 7x7 of Φ1, I think that the lower limit of the pulley diameter is around 20-40mm. If the bending radius is too small, the bending stress of the rope seems to be too large. Larger pulleys take up more space, so I decided to model the pulley diameter as Φ20.

I tried modeling

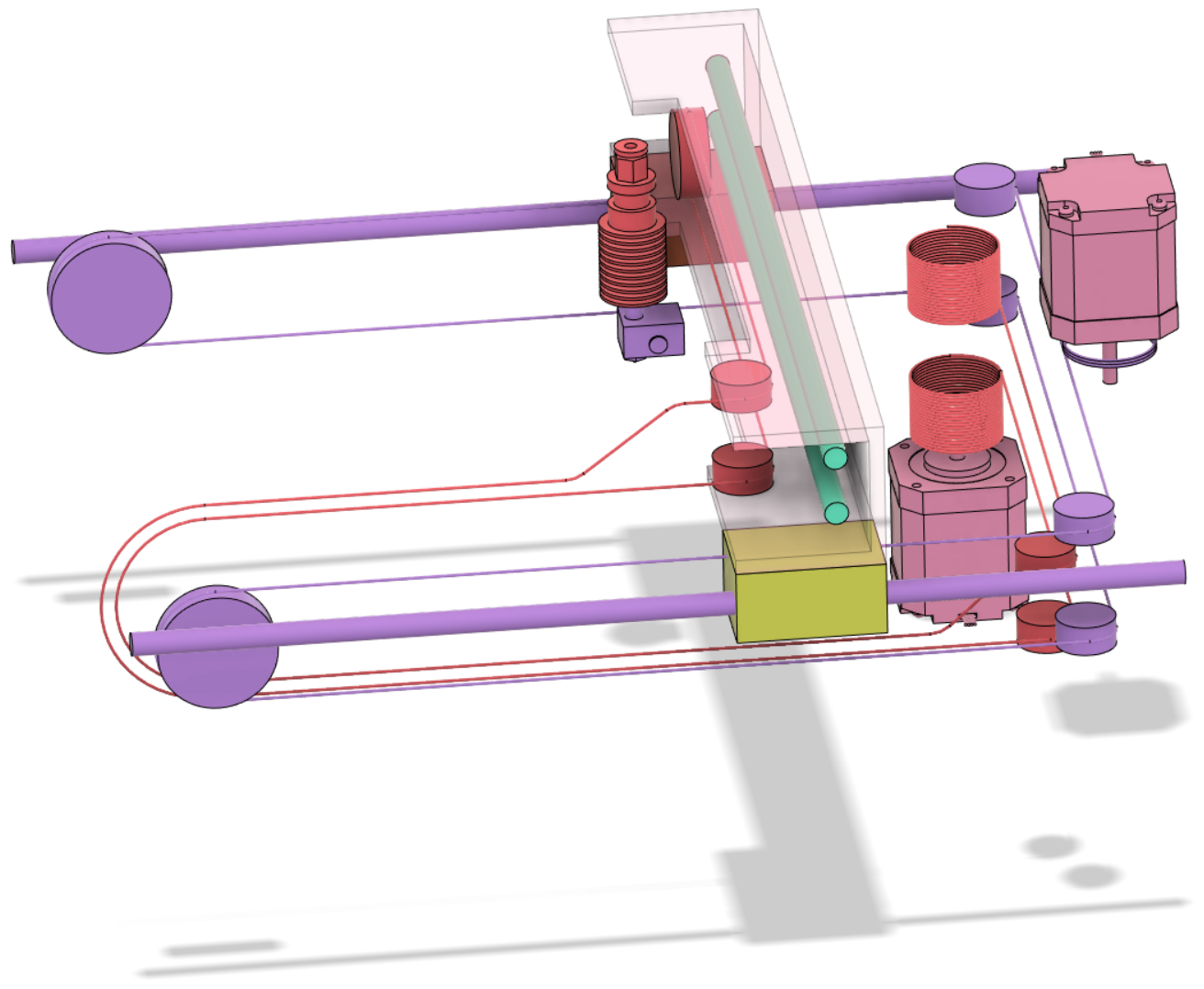

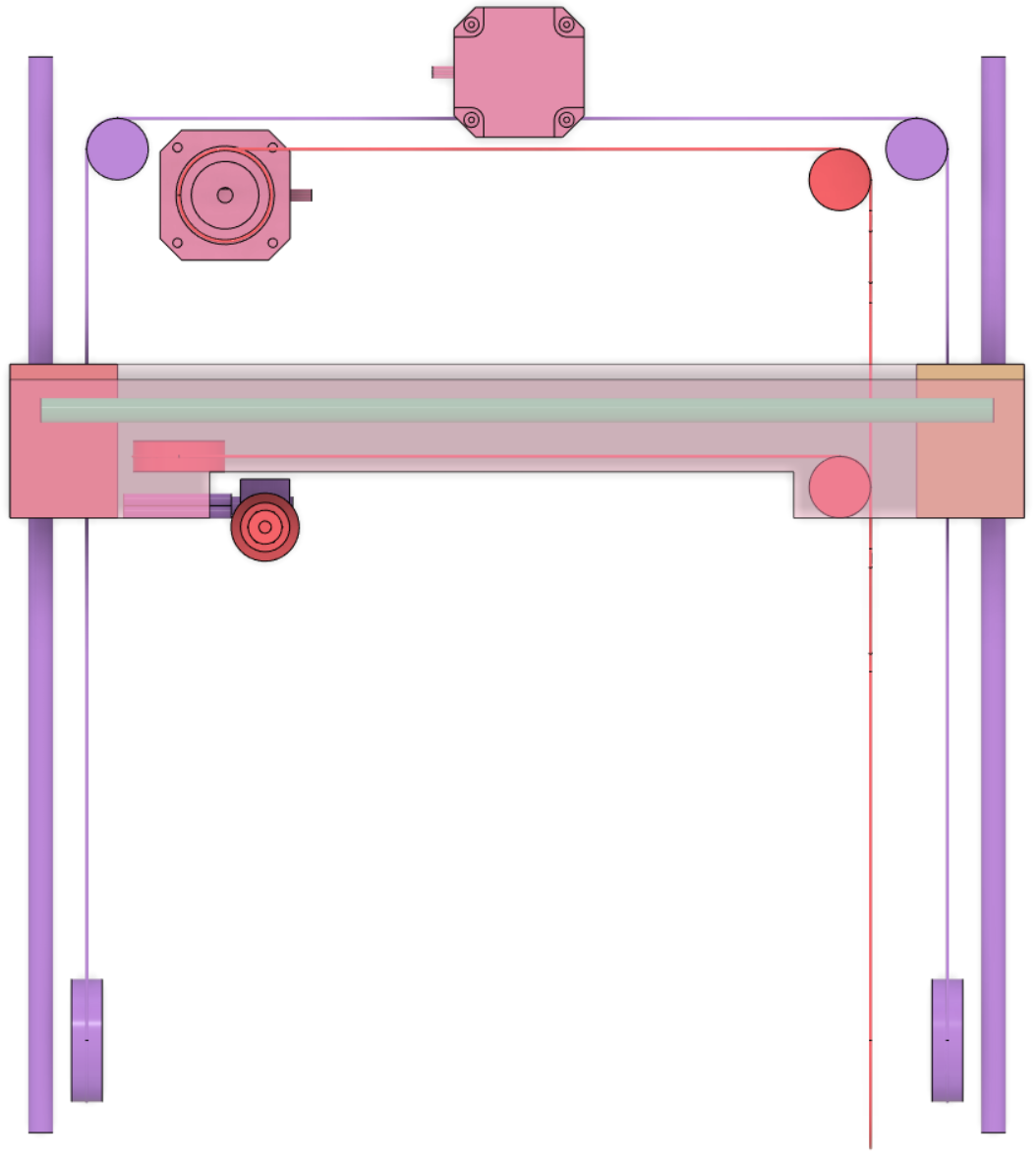

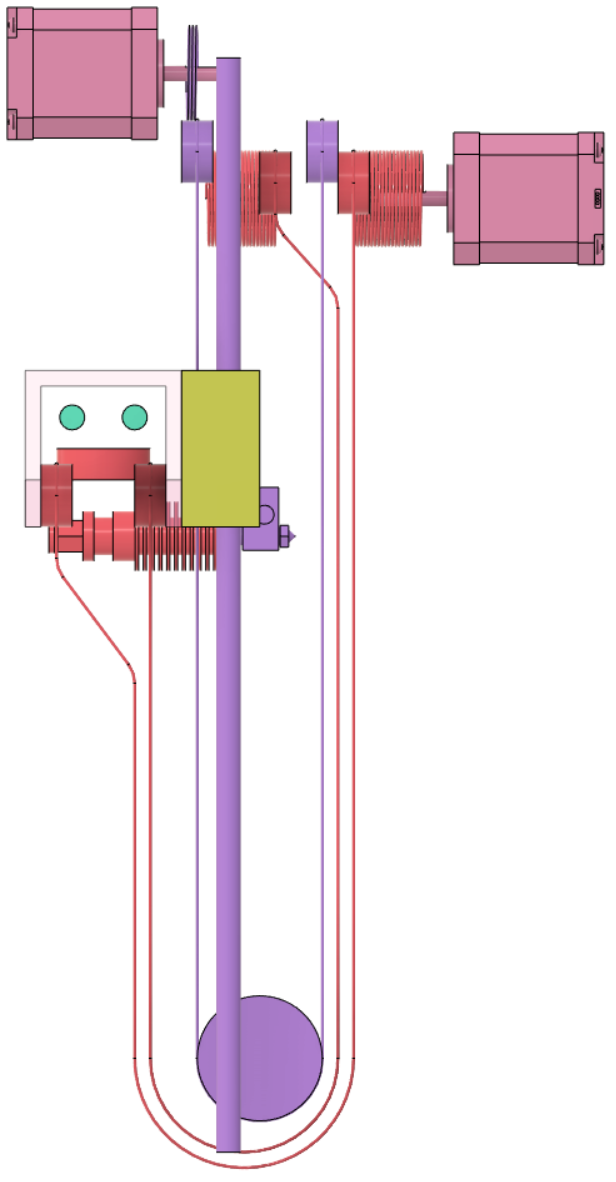

For the time being, I arranged the main parts. The red wire is for the X-axis and the purple is for the Y-axis. I wanted to prevent both the X and Y motors from becoming a drive load, so I decided not to install them in the drive section. For that reason, if you attach an outer wire to the wire for the X axis and let it pass through the cable carrier, I think that you can drive the X axis from a place away from the moving part.

3D model

Assembly STEP file

STL Files

WiRE_DRIVEN_3DPRINTER.stl

Download